Medical Sewing: Ensuring Compliance with Regulatory and Safety Standards

Medical sewing plays a vital role in the healthcare industry, involving the meticulous design and production of essential medical textiles and...

5 min read

Domico Med-Device Updated on December 30, 2024

Finding the perfect sewing contract manufacturer is a critical decision for businesses looking to outsource their production processes. Whether you're producing apparel, medical textiles, or industrial products, selecting the right partner goes beyond a simple evaluation. You must delve deeply into a potential manufacturer's capabilities, industry expertise, and track record. By taking the time to assess these factors, you can establish a partnership that not only fulfills your current production needs but also supports your company’s growth in the long run. In this guide, we’ll explore key questions to ask when evaluating sewing contract manufacturers. These questions will help you avoid common outsourcing pitfalls and identify a reliable, competent partner who can deliver consistent quality and on-time production.

Outsourcing to a sewing contract manufacturer is a strategic move that can streamline operations and reduce overhead costs. However, choosing the wrong partner can lead to delays, quality issues, and financial losses. A thorough vetting process ensures that your manufacturer has the technical skills, resources, and experience needed to meet your production goals.

The right manufacturer will act as an extension of your business, helping you scale operations, maintain quality standards, and meet market demands. But how do you find such a partner? By asking the following critical questions.

Experience is a key indicator of a manufacturer's expertise and reliability. An experienced sewing contract manufacturer brings refined skills, an in-depth understanding of various sewing techniques, and knowledge of industry-specific requirements.

When evaluating potential partners, ask:

An experienced partner is better equipped to anticipate challenges, provide innovative solutions, and maintain high standards throughout the production process.

Understanding a manufacturer’s production capacity and lead times is essential for planning your operations effectively. This ensures they can handle your current order volume and scale production as your business grows.

Key questions to ask include:

A capable manufacturer will have systems in place to manage production efficiently, ensuring on-time delivery and minimal disruption to your operations.

A reliable sewing contract manufacturer should be able to demonstrate the quality of their work through samples and client testimonials. These insights can help you evaluate their craftsmanship, attention to detail, and overall reliability.

![30577 [AD7 Bariatric Table Extender Straps] #7-4](https://www.domicomed.com/hs-fs/hubfs/30577%20%5BAD7%20Bariatric%20Table%20Extender%20Straps%5D%20%237-4.png?width=400&height=152&name=30577%20%5BAD7%20Bariatric%20Table%20Extender%20Straps%5D%20%237-4.png) When assessing past work:

When assessing past work:

By reviewing tangible examples of their work and hearing directly from other businesses, you can gauge whether the manufacturer aligns with your expectations.

Quality control is a non-negotiable aspect of contract sewing. Manufacturers with robust quality control processes can consistently deliver products that meet your specifications, reducing the risk of defects and returns.

Questions to ask about quality assurance include:

Understanding these measures will give you confidence that the manufacturer prioritizes quality and delivers products that meet your standards.

Transparent pricing and fair payment terms are essential for building a strong business relationship. Before signing any contracts, make sure you have a clear understanding of the manufacturer’s pricing model and financial policies.

Key considerations include:

Clear financial communication helps prevent misunderstandings and ensures that both parties are aligned on expectations.

Scalability is a crucial factor when selecting a sewing contract manufacturer. As your business grows, your production needs may increase. A good manufacturer should have the capacity and resources to grow with you.

Questions to ask:

Choosing a manufacturer who can adapt to your changing needs will save you the hassle of transitioning to a new partner as your business expands.

Domico Med-Device exemplifies the benefits of outsourcing sewing to a contract manufacturer. Our capabilities, extensive experience, and commitment to excellence make it a preferred partner for businesses seeking high-quality sewn components for medical devices.

With years of experience and an eye for detail, we ensure quality is stitched into every seam. Processing a wide variety of fabrics and films, our skilled sewing team produces a broad range of products and accessories, including security straps, fabric covers, and assemblies. With our diverse background, there are few sewing needs that we can’t address.

Domico Med-Device utilizes state-of-the-art sewing equipment and techniques to produce high-quality components. Our capabilities include:

Skilled sewing team with extensive experience in medical device manufacturing

Ability to process a wide variety of fabrics and films

Production of a broad range of products and accessories, including security straps, fabric covers, and assemblies

Attention to detail and commitment to quality in every seam

Our team of experts assists clients in selecting the optimal materials for their specific applications. We work with a wide range of fabrics and films, ensuring that our sewn components meet the required performance and safety standards. This material expertise is essential for producing durable and reliable products.

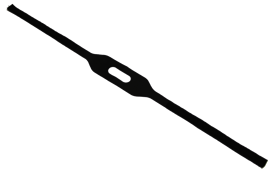

Security Straps are versatile devices used to secure patients to beds or tables. They are designed to prevent accidental movement, which could jeopardize the success of various medical procedures

Chin straps are designed to secure a patient’s head and jaw, providing crucial support during various medical procedures. These straps are particularly important in settings where maintaining precise head positioning is necessary for successful outcomes.

![9409 [CT 850-870 Table Pad] #1-2](https://www.domicomed.com/hs-fs/hubfs/9409%20%5BCT%20850-870%20Table%20Pad%5D%20%231-2.png?width=300&height=200&name=9409%20%5BCT%20850-870%20Table%20Pad%5D%20%231-2.png)

Canon Interventional Table pads made of layered foam to maximize patient comfort. Designed to fit a variety of Canon Tabletops.

ISO 13485 Certification and Regulatory Compliance

ISO 13485 Certification and Regulatory ComplianceDomico Med-Device is ISO 13485 certified, demonstrating our commitment to the highest standards of quality management in the medical device industry. We adhere to all FDA regulations, ensuring that our sewing processes meet the stringent requirements for medical device components. Our rigorous quality assurance protocols and comprehensive testing procedures guarantee the safety and efficacy of our products.

Sewing plays a crucial role in the manufacturing of medical devices, providing customized solutions that enhance patient comfort, safety, and overall device performance. Outsourcing sewing to contract manufacturers like Domico Med-Device offers numerous benefits, including access to specialized expertise, cost efficiency, scalability, and stringent quality assurance. Domico Med-Device exemplifies the advantages of this approach through its advanced capabilities, extensive experience, and commitment to excellence. By partnering with contract manufacturers, businesses can enhance their product offerings, improve operational efficiency, and ultimately deliver better outcomes for their customers.

Have an idea for a medical device? Contact us today to bring your product to life!

Want to learn more? Check out these blog posts to read more about medical device manufacturing:

Medical sewing plays a vital role in the healthcare industry, involving the meticulous design and production of essential medical textiles and...

Medical device manufacturing is gaining traction as companies recognize the benefits of relocating production closer to home. For organizations...

In the intricate world of medical device manufacturing, various specialized processes play a pivotal role in ensuring that products meet the highest...