4 Reasons Why Patient Positioning Aids During Radiological Exams Are Important

Radiological exams are pivotal in diagnosing and monitoring numerous medical conditions. To obtain the most accurate results, patient positioning...

4 min read

Domico Med-Device Updated on December 2, 2024

As technology advances in the medical field, the use of closed-cell foam in patient positioning devices is becoming increasingly popular. With its unique properties such as radiolucency, durability, and ease of cleaning, closed-cell foam offers a superior alternative to traditional materials. Healthcare facilities can benefit from cost savings, improved imaging clarity, and enhanced patient safety by making the switch to closed-cell foam. As the healthcare industry continues to evolve, embracing closed-cell foam as the standard material for patient positioning devices is a smart and forward-thinking decision.

Understanding Closed Cell Foam: The Basics

Understanding Closed Cell Foam: The BasicsClosed cell foam is a type of foam characterized by its non-porous, cross-linked structure. Unlike open-cell foam, which has interconnected pockets that allow air and liquids to pass through, closed-cell foam has individual cells that are completely sealed off. This unique structure gives closed cell foam its distinct properties, making it highly suitable for use in medical settings where cleanliness, durability, and imaging clarity are paramount.

The manufacturing process for closed-cell foam involves creating a foam that is not only dense but also flexible and lightweight. The result is a material that can be easily shaped into various forms, such as foam pads and positioning wedges, without losing its structural integrity. This versatility, combined with the foam’s inherent properties, makes it a superior choice for patient positioning devices in radiology, surgery, and other medical applications.

One of the standout features of closed-cell foam is its radiolucency. In medical imaging, radiolucency refers to a material’s ability to allow X-rays or other imaging rays to pass through without creating artifacts. Artifacts are unwanted marks or shadows that can appear on an image, potentially leading to misinterpretation or misdiagnosis.

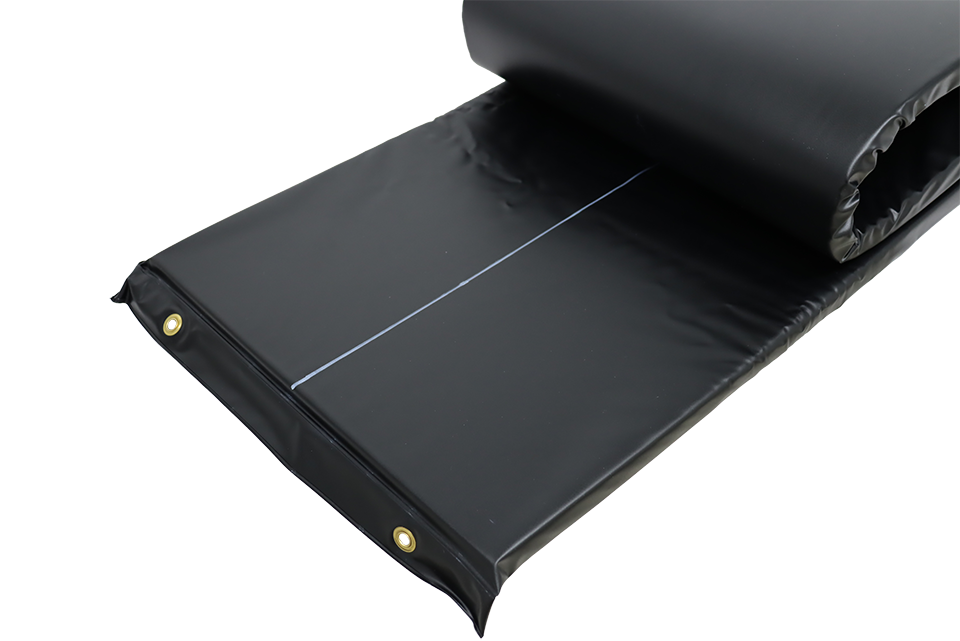

Traditional positioning devices, such as coated or vinyl-covered foam pads, can introduce artifacts because the coating or covering material may not be completely radiolucent. This can result in lines or shadows that interfere with the clarity of the image, particularly if the patient’s body part is placed near the edges of the foam. Closed cell foam, on the other hand, is entirely radiolucent. This means that foam pads and positioning wedges made from this material do not produce any artifacts, ensuring that the primary field of view remains clear and unobstructed. This feature is especially important in diagnostic imaging, where the accuracy of the image is critical for effective patient care.

Medical environments are demanding, with equipment and devices subjected to frequent use and rigorous cleaning protocols. Closed-cell foam is designed to withstand these challenges. The foam’s dense, non-porous structure makes it highly resistant to wear and tear, even under continuous use.

Foam pads and positioning wedges made from closed-cell foam are known for their longevity. Unlike traditional sponges, which may degrade over time due to exposure to cleaning chemicals or repeated use, closed-cell foam retains its shape and functionality for longer periods. This durability translates to cost savings for healthcare facilities, as the need for frequent replacements is significantly reduced.

In healthcare settings, maintaining a clean and sterile environment is essential. Closed-cell foam excels in this area due to its non-porous surface, which does not absorb liquids. This characteristic not only prevents the growth of bacteria and fungi but also makes the foam easy to clean and sanitize.

After each use, foam pads and positioning wedges made from closed-cell foam can be wiped down with standard, non-bleach-based cleaning solutions. The material’s resistance to moisture ensures that it does not harbor pathogens, making it a safer option for patients. Additionally, because closed cell foam does not require a coating or cover, there is no risk of chemical exposure from degraded coatings over time, further enhancing patient safety.

Despite its many advantages, closed-cell foam is often more affordable than other options, such as coated or vinyl-covered foam. This cost-effectiveness is particularly noteworthy given the foam’s superior performance in key areas such as radiolucency, durability, and hygiene.

The manufacturing process for closed-cell foam has historically been complex and costly, which limited its use in the medical field. However, advancements in technology and manufacturing techniques have made it possible to produce closed-cell foam more efficiently and at a lower cost. As a result, healthcare facilities can now access high-quality, durable positioning devices without exceeding their budgets.

Addressing Common Misconceptions About Closed Cell Foam

Addressing Common Misconceptions About Closed Cell FoamWhile closed-cell foam offers numerous benefits, some misconceptions about its appearance and use persist. One common concern is the presence of surface imperfections on foam pads and positioning wedges. Because closed-cell foam does not require a coating or cover, the outer layer may show slight smudges, nicks, or other marks that are a natural result of the manufacturing process. It’s important to note that these surface variations are purely cosmetic and do not affect the functionality or safety of the device.

Another misconception is that coated sponges are superior because they have a smooth, uniform appearance. While coated sponges may look more polished, the coating can introduce artifacts in imaging, as mentioned earlier. Closed cell foam, with its artifact-free properties, offers a significant advantage in ensuring clear and accurate diagnostic images.

The healthcare industry is constantly evolving, with new technologies and materials being introduced to improve patient care. Closed cell foam represents a significant advancement in the field of patient positioning devices, offering a combination of radiolucency, durability, hygiene, and cost-effectiveness that is unmatched by traditional materials.

As more healthcare providers become aware of the benefits of closed-cell foam, its use in medical settings is likely to increase. Whether used in foam pads, positioning wedges, or other patient positioning devices, closed-cell foam is poised to become the standard material for ensuring patient comfort, safety, and accurate imaging results.

For healthcare facilities looking to enhance their imaging capabilities and improve patient outcomes, transitioning to closed-cell foam positioning devices is a smart decision. The benefits are clear: artifact-free imaging, easy maintenance, long-lasting durability, and cost savings. Moreover, with advancements in manufacturing making closed-cell foam more accessible than ever, there has never been a better time to make the switch.

In conclusion, closed-cell foam is not just a material—it’s a game-changer in the world of patient positioning devices. By embracing this innovative material, healthcare providers can ensure that their patients receive the highest standard of care, while also optimizing the efficiency and effectiveness of their imaging procedures. Don’t let outdated materials compromise your facility’s performance; invest in closed-cell foam pads and positioning wedges today and experience the difference for yourself.

Want to learn more? Check out these blog posts to read more about foam positioning aids:

Radiological exams are pivotal in diagnosing and monitoring numerous medical conditions. To obtain the most accurate results, patient positioning...

In any healthcare setting, from emergency rooms to diagnostic imaging centers and surgical theaters, the quality of table pads plays a crucial role...