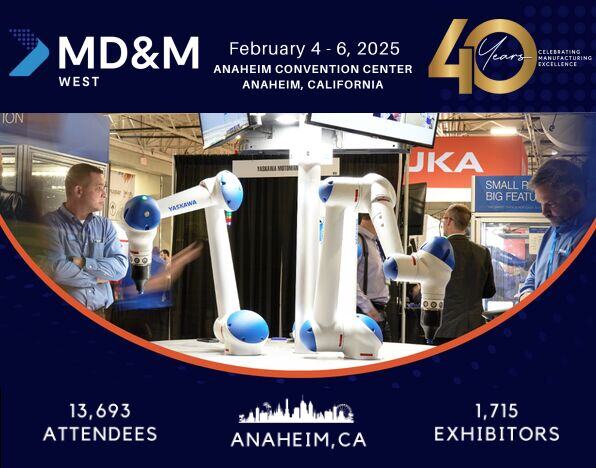

Join Domico Med-Device at MD&M West 2025

We’re thrilled to announce that Domico Med-Device will be exhibiting at MD&M West 2025, one of the largest and most influential events for the...

5 min read

Domico Med-Device Updated on December 2, 2024

The manufacturing of medical devices is a complex and highly regulated process that demands precision, reliability, and adherence to strict quality standards. Product assembly is one of the most critical stages in this process, where individual components are brought together to form a fully functional device. This blog post explores the importance of product assembly in the medical device industry, highlights the benefits of outsourcing assembly to contract manufacturers, and showcases how Domico Med-Device excels in this domain.

Product assembly involves the integration of various components into a complete device. This stage is crucial because it determines the medical device's final functionality, reliability, and safety. Given the stringent requirements and regulations in the medical field, meticulous attention to detail is essential during assembly to ensure that the device performs as intended and meets all regulatory standards.

Challenges in product assembly are multifaceted and require a keen attention to detail.

Precision and Accuracy

Precision and AccuracyThe assembly of medical devices requires a high degree of precision and accuracy. Components must be aligned perfectly, and connections must be secure to ensure the device functions correctly. Even minor deviations can result in malfunction or failure, potentially jeopardizing patient safety. Therefore, skilled technicians and advanced assembly techniques are essential to achieve the required precision.

Medical devices are subject to rigorous regulatory standards set by organizations such as the FDA and ISO. These standards ensure that devices are safe and effective for use in medical settings. Compliance with these regulations involves extensive documentation, testing, and validation throughout the assembly process. Manufacturers must maintain detailed records and perform regular inspections to ensure adherence to these standards.

Medical devices often comprise numerous intricate components, including mechanical, electrical, and electronic parts. Integrating these components into a cohesive system requires specialized knowledge and expertise. The complexity of modern medical devices necessitates a deep understanding of various engineering disciplines and assembly techniques to ensure seamless integration.

Given the challenges associated with product assembly, outsourcing this stage to contract manufacturers offers several advantages. Contract manufacturers specialize in the assembly of medical devices and possess the necessary expertise, equipment, and facilities to handle complex projects efficiently.

Expertise and Specialization

Expertise and SpecializationContract manufacturers have extensive experience and specialized knowledge in assembling medical devices. Their expertise ensures that devices are assembled correctly, minimizing the risk of errors and defects. By leveraging the skills of these professionals, businesses can benefit from higher-quality products and reduced time-to-market.

Outsourcing product assembly can be more cost-effective than maintaining in-house assembly operations. Contract manufacturers have already invested in the required infrastructure, equipment, and personnel. Partnering with them allows businesses to avoid the significant capital expenditures associated with setting up and maintaining their own assembly facilities.

Contract manufacturers offer scalability and flexibility, allowing businesses to adjust production volumes according to demand. This capability is particularly beneficial for companies experiencing fluctuating market demands or launching new products. Contract manufacturers can quickly scale up or down to meet changing requirements, ensuring timely delivery of assembled devices.

Reputable contract manufacturers adhere to stringent quality assurance protocols and regulatory compliance standards. They employ advanced inspection and testing methods to ensure that assembled devices meet the highest quality benchmarks. This commitment to quality reduces the risk of product failures and enhances customer satisfaction.

Domico Med-Device: A Leading Medical Device Manufacturer in Michigan

Domico Med-Device: A Leading Medical Device Manufacturer in MichiganDomico Med-Device exemplifies the benefits of outsourcing product assembly to a contract manufacturer. The company’s advanced capabilities and commitment to excellence make it a preferred partner for businesses seeking high-quality assembled medical devices.

Our design, engineering, and production capabilities at Domico Med-Device culminate with the final assembly and testing of mechanical and electromechanical devices. Built to exact specifications, we carefully construct products to meet the stringent requirements of the medical device industry. The same care is given to contract-manufactured systems, such as MRI coils, CT scanners, and ceiling-mounted accessory suspension systems.

Domico Med-Device utilizes advanced assembly techniques to ensure precision and accuracy. Our skilled technicians are trained to handle complex components and integrate them seamlessly into a cohesive system. We employ state-of-the-art equipment and technologies to achieve the highest levels of precision, reliability, and efficiency in our assembly processes.

Quality assurance is a top priority at Domico Med-Device. We adhere to strict quality control protocols and conduct rigorous testing to ensure that every assembled device meets the highest standards of performance and safety. Our comprehensive testing procedures include functional testing, environmental testing, and compliance testing to verify that devices operate as intended under various conditions.

Domico Med-Device is committed to maintaining compliance with all relevant regulatory standards. We follow industry best practices and adhere to FDA and ISO regulations to ensure the safety and efficacy of our assembled devices. Our thorough documentation and validation processes provide complete traceability and accountability throughout the assembly process.

ISO 13485 Certification

ISO 13485 CertificationDomico Med-Device is proud to be ISO 13485 certified, demonstrating our commitment to the highest standards of quality management in the medical device industry. This certification ensures that our processes, including product assembly, meet international regulatory requirements and consistently deliver safe and effective medical devices.

Carbon Fiber Armboards

Carbon Fiber ArmboardsThe Carbon Fiber Armboards, available at Domico Med-Device, exemplify our product assembly capabilities. These surgical armboards are made of carbon fiber, a material known for its lightweight and high-strength properties. During the assembly process, we attach mounts to the armboards, ensuring they are securely fitted and ready for use in surgical settings. The precision and care involved in assembling these armboards highlight our expertise in handling complex components and delivering high-quality products.

Philips AD7 Mayfield Carbon Fiber Table Extender

Philips AD7 Mayfield Carbon Fiber Table ExtenderAnother example of our product assembly capabilities is the Philips AD7 Mayfield Carbon Fiber Table Extender. This surgical table extender adapts the Philips AD7 Neurology tabletop for craniotomies. The assembly process involves attaching table mounts and rails that allow cranial fixation devices to be securely mounted. Our meticulous assembly process ensures that the table extender meets the exacting standards required for neurosurgical procedures, providing reliable performance and patient safety.

Contract medical manufacturing involves partnering with specialized companies to produce medical devices and components. This collaboration leverages the expertise, advanced technologies, and facilities of contract manufacturers to deliver high-quality products. Domico Med-Device is a prime example of how contract manufacturing can benefit businesses in the medical industry.

Medical Device Manufacturers in Michigan

Medical Device Manufacturers in MichiganMichigan is home to numerous medical device manufacturers known for their innovation and excellence. These manufacturers, including Domico Med-Device, play a crucial role in advancing the medical field. By offering state-of-the-art product assembly services, they help medical device companies develop and produce cutting-edge products that meet the highest standards of quality and performance.

Domico Med-Device is dedicated to delivering superior quality products through its advanced product assembly capabilities. The company’s expertise in material handling, precision assembly, and process optimization ensures that every product meets stringent quality standards. By adhering to rigorous quality assurance protocols, Domico Med-Device provides reliable, durable, and high-performance assembled devices to its clients.

Product assembly plays a crucial role in the manufacturing of medical devices, determining the final functionality, reliability, and safety of the products. Outsourcing product assembly to contract manufacturers like Domico Med-Device offers numerous benefits, including access to specialized expertise, cost efficiency, scalability, and stringent quality assurance. Domico Med-Device exemplifies the advantages of this approach through its advanced capabilities and commitment to excellence. By partnering with contract manufacturers, businesses can enhance their product offerings, improve operational efficiency, and ultimately deliver better outcomes for their customers.

Have an idea for a medical device? Contact us today to bring your idea to life!

Want to learn more? Check out these blog posts to learn more about contract manufacturing:

We’re thrilled to announce that Domico Med-Device will be exhibiting at MD&M West 2025, one of the largest and most influential events for the...

Image-guided therapy (IGT) represents a transformative approach in modern medicine, combining advanced imaging techniques with therapeutic...

In medical device manufacturing, efficiency isn’t just about saving time—it’s about ensuring patient safety and meeting strict quality standards....