3 Types of Sealing and Their Applications for Medical Devices

In the medical device industry, sealing is a critical process that ensures the durability, cleanliness, and biocompatibility of products. Different...

5 min read

Domico Med-Device Updated on December 30, 2024

Carbon fiber is a versatile composite material suitable for a wide range of applications. It is known for its exceptional tensile strength, high flexibility, and resistance to environmental factors such as heat, moisture, and corrosion. These properties make it a go-to material for industries requiring both durability and performance, including the medical sector. It is durable, lightweight, heat and corrosion-resistant, and has great potential in the medical industry.

The medical industry is continuously evolving and innovating, with new technologies demanding the best materials—carbon fiber being one of them. Compared to traditional materials like titanium and stainless steel, carbon fiber stands out for its superior strength-to-weight ratio and exceptional durability. While titanium is known for its robustness and biocompatibility, it is heavier than carbon fiber. Similarly, stainless steel offers excellent corrosion resistance but lacks the lightweight advantage of carbon fiber. These distinctions make carbon fiber a preferred choice for advanced medical applications, ensuring both efficiency and patient comfort.

The medical industry is continuously evolving and innovating, with new technologies demanding the best materials—carbon fiber being one of them. Compared to traditional materials like titanium and stainless steel, carbon fiber stands out for its superior strength-to-weight ratio and exceptional durability. While titanium is known for its robustness and biocompatibility, it is heavier than carbon fiber. Similarly, stainless steel offers excellent corrosion resistance but lacks the lightweight advantage of carbon fiber. These distinctions make carbon fiber a preferred choice for advanced medical applications, ensuring both efficiency and patient comfort.

The use of carbon fiber in healthcare has revolutionized the design and manufacturing of medical devices, resulting in more efficient and effective treatments for patients. This article explores seven key applications of carbon fiber in healthcare, ranging from advanced imaging equipment and surgical tools to innovative uses in prosthetics, wheelchairs, and skeletal implants. These applications highlight carbon fiber's unique properties, including its strength, lightweight nature, and radiolucency, which make it a game-changer in modern medicine.

uses in prosthetics, wheelchairs, and skeletal implants. These applications highlight carbon fiber's unique properties, including its strength, lightweight nature, and radiolucency, which make it a game-changer in modern medicine.

Carbon fiber is extensively used in the construction of imaging equipment such as MRI machines, CT scanners, and X-ray machines. These advancements in radiology technology benefit from carbon fiber's unique properties, which ensure optimal performance in transferring radiation and maintaining structural integrity. Its role in medical imaging advancements further underscores its importance in modern healthcare. These devices require components that can  withstand powerful magnetic fields and radiation. Carbon fiber’s strength and lightweight nature make it an ideal choice for transferring radiation efficiently while maintaining structural integrity. Additionally, its radiolucent properties allow carbon fiber to be nearly invisible to X-rays and other imaging technologies. This means that carbon fiber components do not interfere with the clarity of diagnostic images, providing doctors with unobstructed views of the area being examined. This characteristic is particularly beneficial in imaging equipment, as it ensures that the materials used do not compromise the quality of the images produced, thereby enhancing the accuracy of diagnoses and the effectiveness of subsequent treatments.

withstand powerful magnetic fields and radiation. Carbon fiber’s strength and lightweight nature make it an ideal choice for transferring radiation efficiently while maintaining structural integrity. Additionally, its radiolucent properties allow carbon fiber to be nearly invisible to X-rays and other imaging technologies. This means that carbon fiber components do not interfere with the clarity of diagnostic images, providing doctors with unobstructed views of the area being examined. This characteristic is particularly beneficial in imaging equipment, as it ensures that the materials used do not compromise the quality of the images produced, thereby enhancing the accuracy of diagnoses and the effectiveness of subsequent treatments.

Surgical instruments like forceps, retractors, and scissors often demand materials that are lightweight, reliable, and sterile. Carbon fiber meets these requirements and offers added benefits. It is corrosion-resistant, easy to sterilize, and can withstand high temperatures. These attributes make carbon fiber an excellent choice for creating durable and effective surgical tools, enhancing precision and safety in operating rooms.

Prosthetics require materials that combine strength and flexibility to endure repeated use. Carbon fiber is a prime candidate for prosthetics due to its exceptional strength-to-weight ratio. Lightweight prosthetics improve user comfort and mobility, while the material’s durability ensures long-term reliability. Moreover, carbon fiber’s adaptability enables quick production times and customization to meet individual patient needs, making it ideal for prototyping and personalized solutions.

Durability and ease of use are critical factors for wheelchairs. Traditional materials like steel or titanium are strong but heavy, leading to potential fatigue for users. Carbon fiber offers the same level of strength as steel while being significantly lighter. This reduces the overall weight of the wheelchair, making it easier to carry, store, and maneuver. The lightweight nature of carbon fiber enhances user comfort and minimizes physical exertion, allowing wheelchair users to remain active for longer periods.

Medical implants, including heart monitors and pacemakers, require materials that are lightweight, durable, and biocompatible. Carbon fiber fulfills all these criteria, with the added advantage of being non-reactive to the body’s immune system. Its biocompatibility ensures that implants made from carbon fiber can remain in the body for years without triggering adverse reactions, making it a reliable material for long-term medical solutions.

In cases of large traumatic wounds, the body may struggle to heal itself. A promising solution involves providing a scaffold that supports new cell growth. Carbon fiber has potential as a cell regeneration matrix, offering a framework for fresh cells to rebuild tissue. For example, a study published in Biomaterials Science demonstrated how carbon-based scaffolds support cell adhesion and proliferation, providing an effective structure for tissue regeneration. Such research underscores the promising role of carbon fiber in advancing regenerative medicine. Once the healing process is complete, doctors can remove the carbon fiber scaffold. This innovative application underscores carbon fiber’s potential in regenerative medicine.

During surgeries, surgeons often use screws or bolts to secure bones in place. However, metal components can be heavy and lead to  complications over time. Carbon fiber presents a viable alternative, potentially replacing materials like bone screws, spinal cages, and intervertebral discs. Its lightweight properties help reduce patient discomfort and recovery times, while its durability ensures fewer complications over the long term. Additionally, the biocompatibility of carbon fiber minimizes the risk of rejection or adverse reactions, making it a safer choice for various skeletal implant applications. Its lightweight, durable, and wear-resistant properties make it an excellent choice for skeletal implants, reducing the risk of complications and improving patient outcomes.

complications over time. Carbon fiber presents a viable alternative, potentially replacing materials like bone screws, spinal cages, and intervertebral discs. Its lightweight properties help reduce patient discomfort and recovery times, while its durability ensures fewer complications over the long term. Additionally, the biocompatibility of carbon fiber minimizes the risk of rejection or adverse reactions, making it a safer choice for various skeletal implant applications. Its lightweight, durable, and wear-resistant properties make it an excellent choice for skeletal implants, reducing the risk of complications and improving patient outcomes.

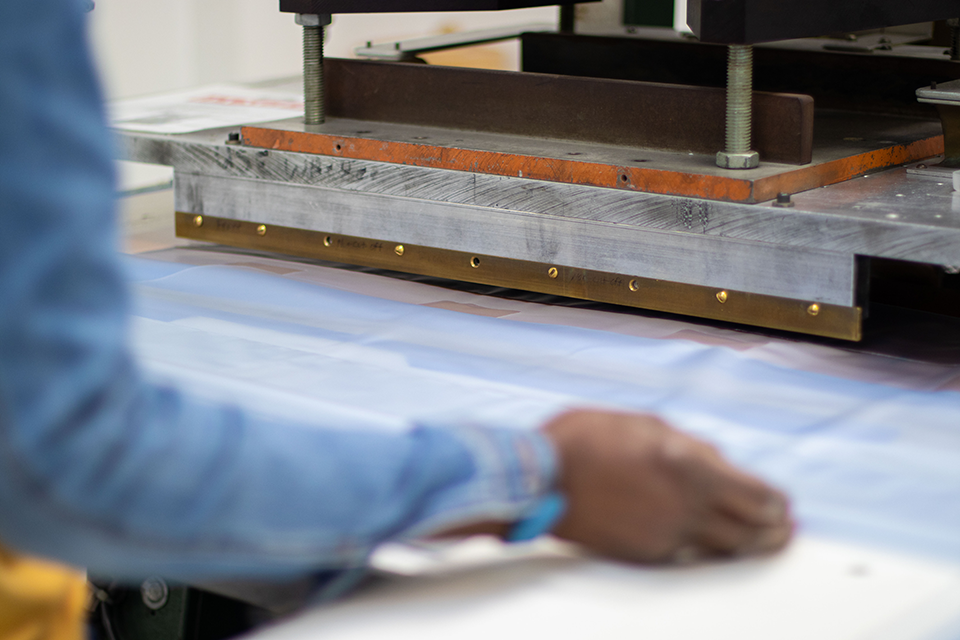

Domico Med-Device has established itself as a leader in carbon fiber manufacturing through its extensive capabilities and expertise. The company’s approach to the challenges of carbon fiber manufacturing is a testament to its commitment to quality and innovation. Here’s a closer look at how Domico Med-Device excels in this field:

company’s approach to the challenges of carbon fiber manufacturing is a testament to its commitment to quality and innovation. Here’s a closer look at how Domico Med-Device excels in this field:

technology enables the company to achieve high levels of accuracy while minimizing material waste. CNC cutting is essential for producing carbon fiber components with consistent dimensions and performance characteristics

technology enables the company to achieve high levels of accuracy while minimizing material waste. CNC cutting is essential for producing carbon fiber components with consistent dimensions and performance characteristicsCarbon fiber is a remarkable material with unique properties that make it invaluable to the medical industry. Its role as an innovative medical material and a component of cutting-edge healthcare technology highlights its potential in transforming patient care and medical advancements. Its biocompatibility, strength, and lightweight nature position it as a strong competitor to traditional materials in medical applications. From imaging equipment to prosthetics and regenerative medicine, the use of carbon fiber in healthcare continues to drive innovation, offering better solutions for patients and medical professionals alike. As research progresses, carbon fiber’s role in transforming the medical field is set to expand, promising a future of enhanced medical technologies and improved patient care.

Do you have an idea for a carbon fiber product? Reach out to us today!

Want to learn more? For more information on contract medical device manufacturing, check out these blogs:

In the medical device industry, sealing is a critical process that ensures the durability, cleanliness, and biocompatibility of products. Different...

Learn about the crucial steps involved in ensuring quality control in the manufacturing of medical devices and why it is important for the healthcare...

Discover the intricate process of EVA compression molding and its importance in the medical device manufacturing industry. Compression molded...