A Complete Guide: Choosing the Right Medical Sewing Contract Manufacturer

Finding the perfect sewing contract manufacturer is a critical decision for businesses looking to outsource their production processes. Whether...

4 min read

Domico Med-Device Updated on December 2, 2024

From understanding your specific needs to evaluating the manufacturer's reputation, we will cover all the essential tips and factors to consider while choosing the right medical device manufacturer.

When choosing a medical device manufacturer, it's important to first understand your specific needs. Consider the type of medical device you require and the specific features or functions it should have. Furthermore, assess from a manufacturing perspective what processes are necessary to create your device, the materials needed for production, and whether you require assistance in designing the part or if you have a finalized design ready for manufacturing. By clearly defining your needs, you can narrow down your options and find a manufacturer who specializes in producing devices that align with your design, material, and manufacturing requirements.

Researching and Evaluating Manufacturer's Reputation

Researching and Evaluating Manufacturer's ReputationAfter understanding your specific needs, the next critical step in selecting the right medical device manufacturer involves actively searching for and vetting potential partners. Start by compiling a list of manufacturers that have the capabilities to meet your requirements. This can be done through industry directories, trade shows, professional networks, and online searches. Once you have a list, conduct a thorough evaluation of each manufacturer.

Look for manufacturers who have a proven track record of producing high-quality medical devices. Read customer reviews and testimonials to get an idea of their reputation in the industry. Additionally, check if the manufacturer has any certifications or accreditations that demonstrate their commitment to quality and compliance. Specifically, ensure they are certified under ISO 13485, which is a clear indication of their adherence to the stringent quality management systems required for the design and manufacture of medical devices. This certification is crucial as it not only reflects their commitment to quality, but also their ability to meet regulatory requirements consistently.

Visit their websites to understand their expertise, technology, and past projects. Reach out to them with inquiries about their experience in producing devices similar to what you need. It's also beneficial to request references or case studies that can provide insights into their working relationships with other clients.

Another effective approach is to schedule visits to the manufacturing facilities of your shortlisted candidates, if feasible. A firsthand look at their operations can offer valuable perspectives on their processes, quality control measures, and the overall professionalism of their team. Additionally, engage in discussions about your project to gauge their responsiveness, interest, and ability to provide innovative solutions or suggestions.

By taking these steps, you can make an informed decision based on a comprehensive understanding of each manufacturer's capabilities, reliability, and commitment to quality. This proactive approach ensures you choose a partner that not only meets your current needs but can also grow with you as your requirements evolve.

In addition to assessing the manufacturer's quality control processes, it is imperative to delve deeper into their commitment to quality and compliance. Look for manufacturers who not only adhere to industry standards and regulations but also go above and beyond to ensure the highest level of quality in their medical devices. This can be demonstrated through a robust quality management system that encompasses every aspect of the manufacturing process, from raw material selection to final product inspection.

Furthermore, a reputable manufacturer will have stringent quality control checkpoints in place at various stages of production. These checkpoints may include thorough inspections, rigorous testing protocols, and precise measurements to guarantee that each medical device meets the required standards of safety, performance, and reliability. By prioritizing quality at every step, manufacturers can assure their clients of the effectiveness and safety of the devices they produce.

Moreover, it is essential to consider whether the manufacturer has a comprehensive compliance program in place to meet regulatory requirements. A strong emphasis on compliance not only ensures that the devices meet the necessary regulatory standards but also reflects the manufacturer's commitment to ethical practices and patient safety. By choosing a manufacturer with a robust quality management system and a dedication to compliance, you can have confidence in the reliability and efficacy of the medical devices they produce.

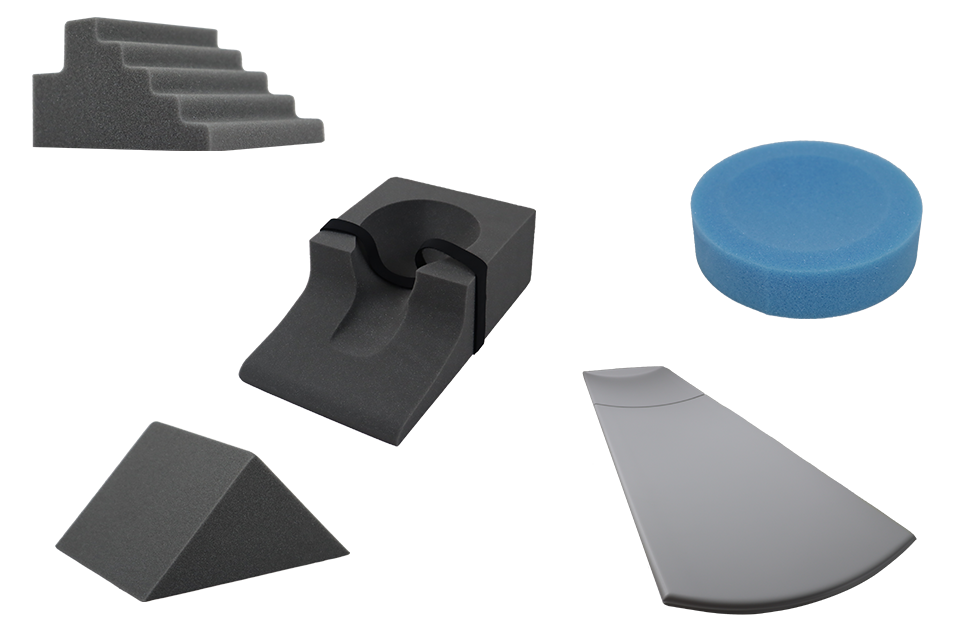

When reviewing the manufacturer's product range and customization options, it is crucial to delve deeper into the variety of medical devices they offer. Look for manufacturers that not only cater to a wide range of medical specialties but also demonstrate expertise in producing innovative and cutting-edge devices. Consider whether they have a diverse portfolio that includes devices for different healthcare needs, from diagnostic tools to surgical instruments.

Moreover, assessing the customization options provided by the manufacturer is key to ensuring that they can tailor the device to meet your specific requirements. Look for manufacturers that offer flexible customization services, allowing you to personalize the device according to your unique needs and preferences. Whether it's adjusting the size, shape, features, or materials used in the device, a manufacturer with robust customization capabilities can better accommodate your demands and ensure that the final product meets your expectations.

Ultimately, choosing a manufacturer with a wide product range and comprehensive customization options not only increases the likelihood of finding a device that aligns with your needs but also showcases the manufacturer's versatility and ability to adapt to different specifications. This flexibility and range of offerings can be instrumental in ensuring that you receive a customized solution that meets your specific requirements and enhances the overall effectiveness of the medical device.

When evaluating the cost of a medical device manufacturer, it's crucial to look beyond just the initial pricing. While finding a manufacturer that offers competitive rates is important, it's equally vital to consider the value you will receive for your investment. In addition to cost, assessing the manufacturer's support services is key to ensuring a successful partnership.

When evaluating the cost of a medical device manufacturer, it's crucial to look beyond just the initial pricing. While finding a manufacturer that offers competitive rates is important, it's equally vital to consider the value you will receive for your investment. In addition to cost, assessing the manufacturer's support services is key to ensuring a successful partnership.

Comprehensive support services, such as technical assistance, training, and after-sales support, can greatly enhance the overall value of your investment. A manufacturer that provides these services can help streamline the manufacturing process, address any issues that may arise, and ensure that you have the necessary resources and guidance every step of the way. Whether it's troubleshooting technical challenges, providing training for your team on how to use the device effectively, or offering ongoing support post-purchase, a manufacturer that prioritizes support services can make a significant difference in your overall experience.

By choosing a manufacturer that not only offers competitive pricing but also prioritizes support services, you can ensure that you receive the most value for your investment. This combination of affordability and comprehensive support can help you navigate the complexities of manufacturing medical devices more effectively and ultimately lead to a smoother and more successful partnership.

Finding the perfect sewing contract manufacturer is a critical decision for businesses looking to outsource their production processes. Whether...

The manufacture of medical devices is a highly specialized and intricate process, requiring precision, expertise, and adherence to stringent...

Compression molding is a critical process in manufacturing durable, high-quality components used in various industries, including medical devices....