Empowering OEMs: The Vital Role of Contract Manufacturers in Customized Medical Devices

Healthcare is undergoing a groundbreaking transformation fueled by technological advancements that are driving the creation of innovative medical...

4 min read

Domico Med-Device Updated on December 2, 2024

The medical device industry is expanding at a steady annual growth rate of approximately 5.68%, making it a lucrative and appealing opportunity for small to medium sized original equipment manufacturers (OEMs). Emerging medical device companies often bring innovative concepts to the table, but they also face a competitive landscape heavily dominated by established corporations. Typically, these larger companies have greater access to resources, advanced infrastructure, and economies of scale, which can pose significant challenges for newer and smaller OEMs.

However, medical device contract manufacturing offers a viable solution for emerging OEMs. By outsourcing production to specialized contract manufacturers, OEMs can overcome industry challenges, improve cost efficiency, and focus on strategic growth.

Manufacturing medical devices independently requires a large capital investment in specialized equipment, infrastructure, and a skilled workforce. Smaller OEMs often lack sufficient revenue to support these costs upfront, relying heavily on investors to build production capacity. This financial constraint can hinder their ability to scale and sustain operations. Working with a contract manufacturer allows these businesses to leverage economies of scale without extensive capital outlay, which is attractive to both investors and stakeholders.

By partnering with an established medical device contract manufacturer, OEMs gain access to vertically integrated production facilities, reducing the need to invest in costly equipment and infrastructure. Contract manufacturers already have skilled teams experienced in medical device production. This arrangement lowers overhead expenses significantly, allowing OEMs to scale production up or down in response to market demands without worrying about idle equipment or high fixed costs.

Access to Specialized Expertise in Medical Device Production

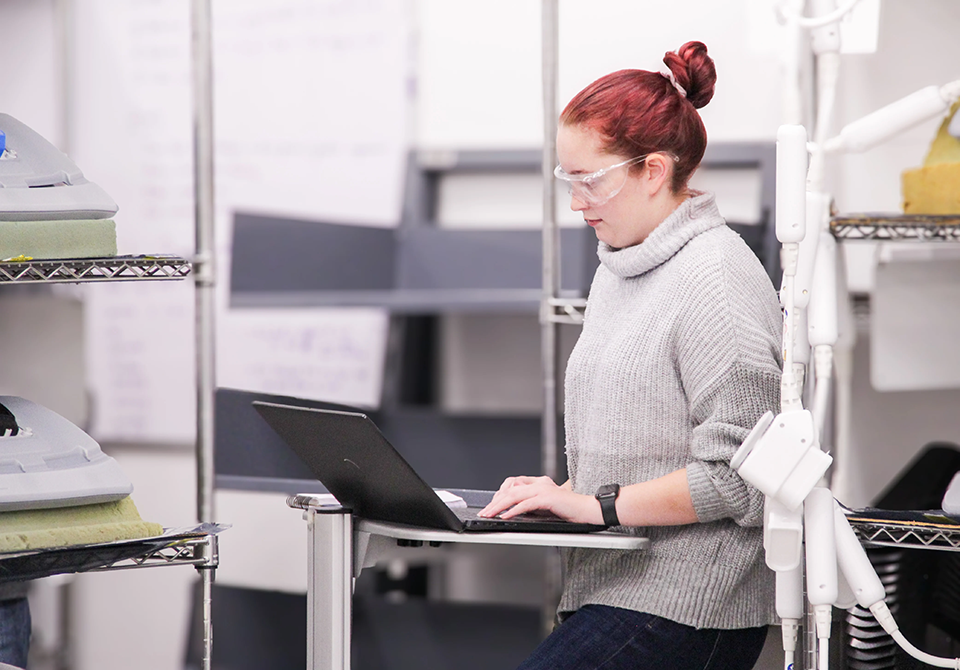

Access to Specialized Expertise in Medical Device Production The medical device industry is highly regulated, with strict federal guidelines and standards such as FDA and ISO certifications. Ensuring compliance requires substantial expertise, particularly for emerging OEMs with limited experience navigating regulatory landscapes. Contract manufacturers specializing in medical devices have seasoned professionals familiar with these regulatory requirements. Their expertise not only increases the likelihood of obtaining necessary certifications but also ensures adherence to quality standards.

A contract manufacturer’s team is often highly skilled and knowledgeable about the latest medical device technologies, processes, and innovations. Instead of hiring in-house experts and investing in continuous training, OEMs can benefit from the contract manufacturer’s existing expertise. This advantage helps companies stay competitive, keeping them updated on state-of-the-art production techniques without significant investment.

The speed at which an emerging OEM can bring a product to market is crucial for gaining a competitive edge. Faster market entry allows a company to start generating revenue sooner, which is vital for growth and sustainability. An experienced contract manufacturer can significantly shorten development timelines, helping OEMs expedite the product lifecycle from prototype to commercialization.

How Contract Manufacturers Support Time-to-Market Goals

How Contract Manufacturers Support Time-to-Market GoalsCompanies like Domico Med-Device use several methods to speed up production and reduce delays:

An established contract manufacturer also benefits from optimized supply chain networks. OEMs that partner with these manufacturers avoid the time-consuming task of building new relationships for sourcing components. Instead, they gain immediate access to an established network for sourcing materials, skilled labor, and advanced technology.

Developing a new medical device presents significant risks, especially for emerging OEMs with limited financial and operational capacity. Potential risks include production downtime, equipment malfunctions, and workforce shortages. A contract manufacturer provides risk mitigation strategies, offering a flexible workforce, operational redundancies, and contingency plans to minimize disruption.

Contract manufacturers are adept at scaling operations to meet fluctuating product demands. When demand spikes, they can allocate additional resources, machinery, and personnel to increase production capacity. Conversely, if demand temporarily decreases, they can scale down production to minimize unnecessary costs for the OEM. This adaptability helps OEMs maintain a lean operation, only paying for the production levels they need.

Some OEMs may initially worry that outsourcing production could compromise product quality. However, reputable contract manufacturers understand the importance of maintaining exceptional quality control to attract and retain clients. Contract manufacturers typically implement stringent quality control systems to ensure consistent product quality and compliance with regulatory standards, significantly reducing the likelihood of defects or recalls.

stringent quality control systems to ensure consistent product quality and compliance with regulatory standards, significantly reducing the likelihood of defects or recalls.

To meet the evolving demands of the healthcare industry, medical device contract manufacturers prioritize continuous process improvements, manufacturing efficiency, and product quality checks. They proactively address potential quality concerns, ensuring that every unit meets the highest standards. This quality-focused approach helps emerging OEMs build trust with healthcare providers, patients, and regulatory authorities.

Selecting the right contract manufacturer is essential for fostering a successful, long-term relationship that promotes business growth. Emerging OEMs should seek partners committed to mutual success and long-term collaboration. Ideally, OEMs will find a manufacturer capable of growing alongside them, accommodating increasing production needs as the OEM expands its product line or enters new markets.

With repeated collaboration, contract manufacturers can fine-tune their processes to meet the OEM’s unique specifications. Over time, it may even become financially feasible for the contract manufacturer to invest in customized equipment tailored to the OEM’s product needs. Long-term relationships often lead to better support, enhanced product development insights, and a deeper understanding of the OEM’s goals.

Contract manufacturing offers a strategic advantage for emerging OEMs in the medical device industry, helping them overcome financial, operational, and regulatory challenges. By partnering with an experienced contract manufacturer, OEMs can focus on innovation and market growth while enjoying cost efficiencies, risk mitigation, and scalable solutions.

Contract manufacturing offers a strategic advantage for emerging OEMs in the medical device industry, helping them overcome financial, operational, and regulatory challenges. By partnering with an experienced contract manufacturer, OEMs can focus on innovation and market growth while enjoying cost efficiencies, risk mitigation, and scalable solutions.

Whether you're ready to accelerate production, improve quality control, or build a long-term manufacturing partnership, contract manufacturing can support your goals. Learn more about how Domico Med-Device can assist your emerging medical device company by contacting us online or calling our office at 810.750.5300.

Have an idea for a medical device? Contact us today to bring your product to life!

Want to learn more? Check out these blog posts to learn more about contract manufacturing

Healthcare is undergoing a groundbreaking transformation fueled by technological advancements that are driving the creation of innovative medical...

Learn about the crucial steps involved in ensuring quality control in the manufacturing of medical devices and why it is important for the healthcare...

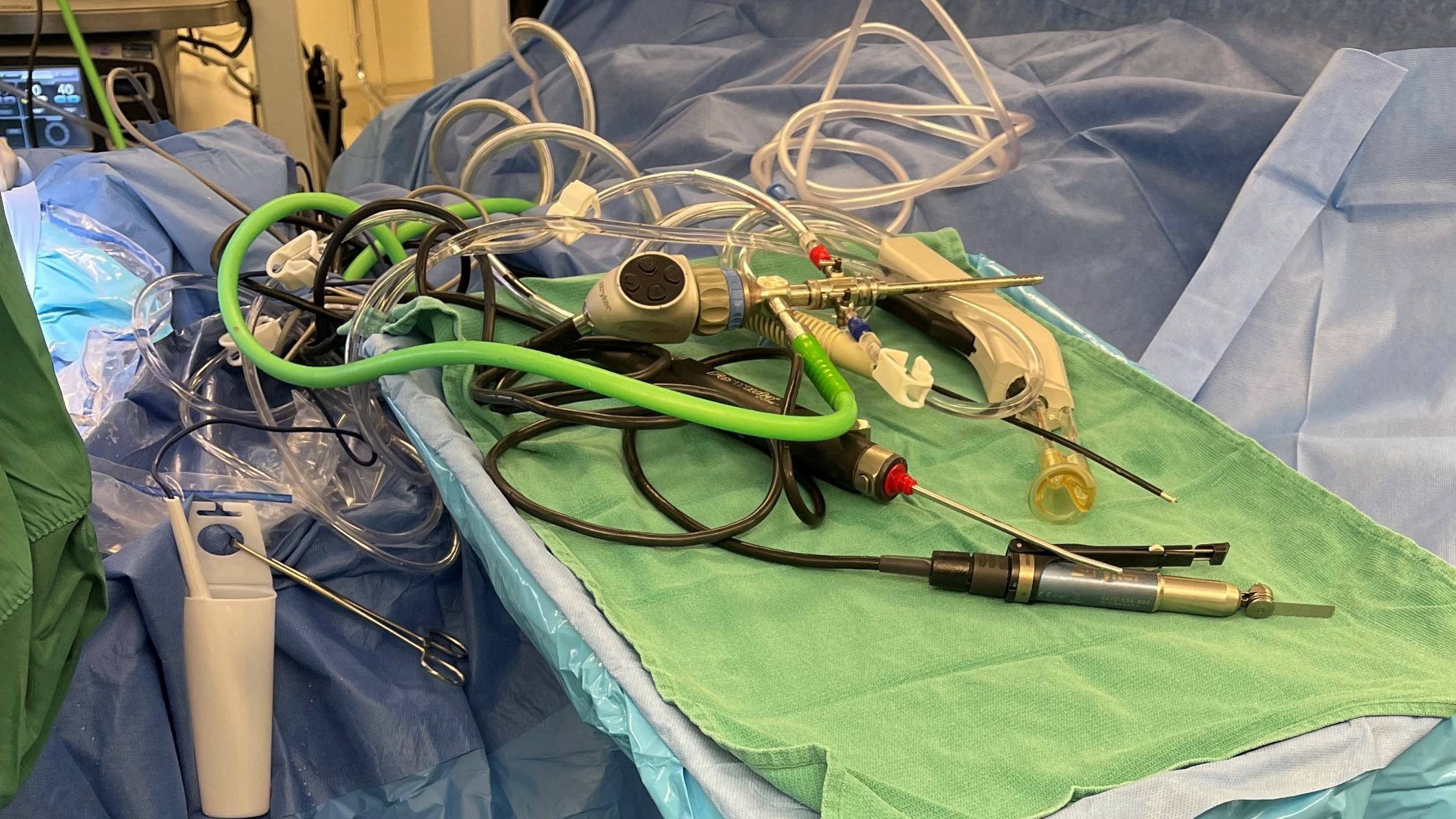

This is Part 1 in a 3-part series on strategic cord management in the operating room. In Part 1, we’ll offer an overview of the safety risks of...