The Crucial Role of Product Assembly in Manufacturing Medical Devices

The manufacturing of medical devices is a complex and highly regulated process that demands precision, reliability, and adherence to strict quality...

Engineers are unsung heroes in medicine, developing incredible imaging technologies that allow caregivers to peer deep into the human body and lend the insights needed to drive better healthcare outcomes. Domico Med-Device’s expertise in manufacturing and patient positioning helps engineers achieve market success.

Common Challenges for Medical Device Engineers

Common Challenges for Medical Device EngineersEngineers and OEMs often face a myriad of challenges when developing medical devices that can revolutionize healthcare. These challenges range from intricate supply chain issues that can create delays and put profits at risk, to the critical task of material selection which impacts everything from manufacturability to patient comfort. Moreover, the ability to efficiently manufacture and scale products is essential for meeting market demand and maximizing ROI. Add in the complexities of testing and regulatory hurdles that can significantly delay time to market, and the importance of patient positioning becomes clear - caregivers need technology that ensures patient comfort and stability to obtain accurate and high-quality images.

Navigating these challenges requires a strategic approach and expertise in various areas. From tackling supply chain obstacles to optimizing material selection for cost-effectiveness and performance, engineers and OEMs must find innovative solutions to bring their products to market successfully. Additionally, ensuring manufacturability and scalability are crucial for meeting demand and staying competitive in the industry. Addressing testing and regulatory requirements is essential for compliance and product safety while prioritizing patient positioning can enhance caregiver adoption and ultimately improve healthcare outcomes.

By collaborating with experienced partners like Domico Med-Device, engineers can overcome these challenges and turn their visions into reality. Through a combination of patient interfacing expertise and advanced manufacturing capabilities, Domico helps engineers design products that seamlessly integrate with technology, optimize for manufacturability, and meet regulatory standards. With a focus on reducing costs, accelerating time to market, and maximizing ROI, Domico empowers engineers to bring innovative medical devices to market that have a positive impact on patient care and healthcare delivery.

How Domico Med-Device Solves Engineer Challenges

How Domico Med-Device Solves Engineer ChallengesAt Domico Med-Device, we pride ourselves on our close collaboration with engineers and OEMs, combining our expertise in patient interfacing with our extensive manufacturing capabilities to bring innovative and profitable products to market.

Our focus is on designing solutions that seamlessly integrate with cutting-edge technology. While engineers create the technology, we ensure that it is not only functional but also comfortable and pain-free for patients. By prioritizing patient comfort, we enable high-quality imaging and increase the likelihood of caregiver adoption, ultimately leading to better healthcare outcomes.

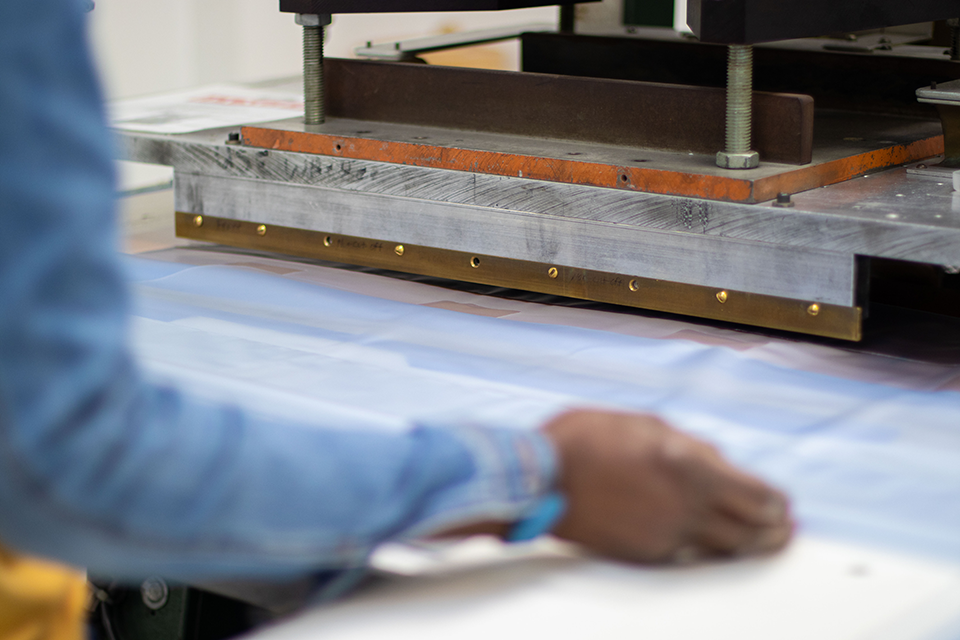

Moreover, we excel in designing for manufacturability by leveraging our extensive network of suppliers to address supply chain challenges and identify the most cost-effective, high-performance materials for each specific application. Through the development of efficient manufacturing processes, we streamline production at scale and minimize waste, ensuring a seamless transition from design to market-ready product.

Additionally, our team is well-equipped to assist with design requirements and regulatory documentation. From conducting necessary testing to verify design specifications to completing essential risk documentation for product safety and effectiveness, we provide comprehensive support every step of the way.

By partnering with Domico Med-Device, engineers can benefit from our holistic approach to product development, reducing costs, accelerating time to market, manufacturing at scale, and maximizing ROI. Our track record of successful collaborations, such as redesigning baby incubator pads to meet updated regulatory requirements or developing innovative attachment devices for surgical tables, showcases our commitment to delivering impactful solutions that improve lives.

Together, let's bring your vision to life and make a difference in healthcare. Contact us today to discover how Domico Med-Device can help turn your ideas into successful products that transform the industry.

Engineer Benefits

Engineer BenefitsReducing costs, accelerating time to market, manufacturing at scale, and maximizing ROI are crucial goals for engineers and OEMs in the medical device industry. By focusing on cost-effective material selection, streamlined manufacturing processes, and efficient supply chain management, companies can significantly reduce costs without compromising quality. Accelerating time to market requires a strategic approach to testing, regulatory compliance, and design optimization, ensuring that products are brought to market quickly and efficiently. Manufacturing at scale involves implementing scalable production methods and leveraging partnerships with reliable suppliers to meet market demand effectively. Maximizing ROI involves making smart investments in product development, marketing, and distribution to ensure long-term profitability and success in the competitive healthcare industry. By prioritizing these key objectives, engineers can achieve market success and drive better healthcare outcomes for patients.

Baby Incubator Pads: Facing compliance issues due to revised EU and Medical Device Remediation (MDR) requirements, a major medical manufacturer turned to Domico to redesign its popular baby incubator pads. We worked alongside the manufacturer to develop a new, easy-to-clean pad that wouldn’t allow fluid to ingress and met the updated regulatory requirements – without disrupting production

Surgical Tables: An innovative OEM designed a revolutionary multi-accessory surgical table that could identify which accessory was mounted to it. Domico developed the attachment device that allowed the table to recognize which accessory was in place and ensured that the device met or exceeded the full system's weight requirement

MRI Coil: An OEM’s engineers designed a new MRI coil to enhance imageability and improve image quality, but the coil was painful for patients. We assisted the engineers by providing a comfort solution that met the needs of the patient and the imaging system, increasing the likelihood of caregiver adoption

At Domico Med-Device, we are dedicated to collaborating with engineers to turn their innovative ideas into successful products that make a meaningful impact in the healthcare industry. Our team is committed to providing comprehensive support throughout the product development process, from design and manufacturing to regulatory compliance and market launch.

By partnering with us, engineers can benefit from our expertise in patient interfacing and advanced manufacturing capabilities, ensuring that their products not only meet market demand but also prioritize patient comfort and caregiver adoption. We understand the challenges that engineers face in developing medical devices, and our strategic approach focuses on reducing costs, accelerating time to market, and maximizing ROI.

Whether it's redesigning baby incubator pads to meet updated regulatory requirements, developing innovative attachment devices for surgical tables, or enhancing MRI coils for improved image quality and patient comfort, we are here to help bring your vision to life. Contact us today to discover how Domico Med-Device can support you in creating transformative solutions that improve lives and drive better healthcare outcomes.

The manufacturing of medical devices is a complex and highly regulated process that demands precision, reliability, and adherence to strict quality...

In medical device manufacturing, efficiency isn’t just about saving time—it’s about ensuring patient safety and meeting strict quality standards....

In the medical device industry, sealing is a critical process that ensures the durability, cleanliness, and biocompatibility of products. Different...